LHT Sinking Spring

WR Meadows, Inc.

Materion - Reading Plant 2

Lehigh Northampton Airport

Commercial Asphalt Supply

Lebanon Water Treatment Facility - Vapor Blasting

Wells Fargo - Vapor Blasting

Allegheny Minerals

Bethlehem Crossings

Berks Products Tanks

Bucknell University Art Barn

Buzzi Unichem

Carpenter Technology

EB Games

Interstate Container Maintenance Shop

Lehigh Crossing Tilt-Up Warehouse

Lenox Building

Blue Mountain Industrial Park

Ocean Spray

PennState Berks Campus

PennState University Nittany Lion

Schneider Electric Aisle-way

Schuylkill Energy Clarifier & Silo

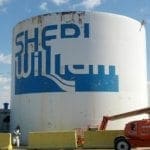

Sherwin Williams Tank

St. Joseph Hospital Satellite

Straight Arrow - Renovation Project

Wakefern Distribution Center

Wells Fargo Office Building

-

LHT Sinking Spring

Lucknow – Highspire Terminals, located in Sinking Spring, Pennsylvania, had multiple tanks, equipment and piping pressure washed and hand tool cleaned to remove any rust or failing areas to prepare for new coatings. All exterior tank walls, roofs, and stairs were primed with Macropoxy Preprime, fast cure epoxy, and polyurethane paint -

WR Meadows, Inc.

W.R. Meadow designs, manufactures, and markets high quality building materials for construction professionals. They are located throughout the US. We work at the York County facility. Our team abrasive blasted the storage tanks and then applied fast cure epoxy and polyurethane. All railings, catwalks, and ladders were painted in safety yellow and all piping was painted as well. The team finished up the project by stenciling the lettering on both tanks. -

Materion - Reading Plant 2

Materion is a metal processing plant, located in Leesport Pennsylvania. At this plant, our team hand grinded and chemically stripped the existing safety lines. Then grinded and abraded the concrete to apply yellow paint to create the new safety lines, which measured out about 2,500 LF. -

Lehigh Northampton Airport

Lehigh Northampton Airport Authority is an airline/aviation company based out of Allentown Pennsylvania. Our team pressure washed and sand grinded the hangar doors to remove all dirt and contaminants, such as rust and old peeling paint. The six doors were then prime coated with fast cure epoxy and painted with polyurethane. Along with the hangar, the aluminum exit/entrance door frames and window frames were all pressure washed/sand grinded, scraped, primed, and painted. -

Commercial Asphalt Supply

Commercial Asphalt Supply, located in Slippery Rock Pennsylvania, specializes in asphalt paving. At this plant our team abrasive blasted exterior asphalt equipment, such as silos, dryer support steel, coal feed bins, conveyors, ductwork, etc. to prepare the surface for new coatings. New coatings included fast cure epoxy, polyurethane and flame control high temperature coating. All railings and ladders were also painted in safety colors. -

Lebanon Water Treatment Facility - Vapor Blasting

-

Bethlehem Crossings

Pressure washed, applied elastomeric paint system, Tilt Up Construction. Location - Bethlehem, Pa -

Bucknell University Art Barn

Bucknell University’s Art Barn was renovated to house Art Classes. The existing wood siding was washed and hand scraped to remove very old bad blistered and peeling paint. Damaged siding was repaired, primed with an oil base primer and finished with two coats of exterior acrylic finish. The old concrete silos were vapor blasted to remove old coatings, primed and finished with a water-based paint system. -

Carpenter Technology

A Carpenter technology logo was applied to the side of new building. The logo was applied using a pounce pattern that is placed over the painted background color and the image is then transferred using chalk. Then the pounce pattern is removed and the transferred outline hand painted with specified company colors. -

EB Games

-

Interstate Container Maintenance Shop

The existing maintenance shop at Interstate Container was in need of a new clean look. Hannahoe Painting vapor blasted the steel ceiling to remove rust and prepare for new coatings. The ceiling was painted with a Dryfall paint and the CMU walls were painted with a water-based epoxy to match the new company colors. -

Lenox Building

Pressure washed, applied elastomeric paint system, Tilt Up Construction. Location - Maryland -

Schneider Electric Aisle-way

Existing floors were laid out to specified dimensions, sanded and painted with a two-part epoxy floor coating. -

Wakefern Distribution Center

A new 1,000,000sqft distribution center involving exterior textured coatings, interior office space, epoxy floors and interior concrete warehouse walls. -

Wells Fargo Office Building

Concrete walkway was mechanically grinded to prepare concrete for new coatings. An anti-skid epoxy coating was applied to the walkway and parking garage bridge.